Hey Friends! I still have a whole rock and roll styled living room to show you, but today I am getting a little off track to show you a table top that we recently designed and fabricated for a favorite client of ours!

We started with a flat table top made from 2in oak boards. Thanks to our friend Lissa for building this piece for us!

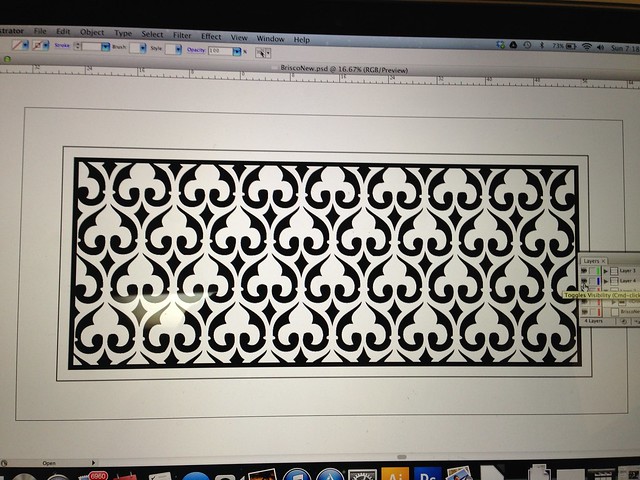

My thought was to create an “engraved” sort of look in the table. So I decided on a pattern and Tim created the computer file necessary for the CNC machine to make my dreams a reality! 🙂

Once the file was created, and the table top was put in place, the CNC began its work of routing out the shapes.

After the CNC had finished it’s work, the table top look like this. . .

Our next step was to stain and poly the table top. . .

And then came the process of filling the voids created by the CNC. I love the combination of wood and concrete, so we used our favorite concrete product (ARDEX) yet again! We simply used a large putty knife to push the mixture into the recessed shapes.

We then used the knife to remove as much excess ARDEX from the top of the table as possible and let it dry.

Once the ARDEX was dry, we used a wet rag to remove it from the wood, leaving the ARDEX in the former voids in tact. Sealing the wood before the applying the ARDEX kept it from adhering to the wood permanently.

A piece of wood covered in a rag was the easiest way to remove the extra ARDEX and not dig into the “engraved” parts of the table top.

Once we finished removing the extra ARDEX and revealed the beautiful oak, we sealed the entire piece with Polyurethane to create a surface suitable for sharing meals and resisting stains! Here’s how it turned out!

We love how it turned out and Brenda (our client) did as well! When are clients are happy, we are happy! Stay tuned to see what we used as a base to complement this beautiful table top in upcoming posts! Happy Wednesday!!!

PS-You can find your local ARDEX distributor right here!

*Disclaimer- We choose to do projects that we believe will enhance homes and be lasting. However, sometimes our applications are not specifically suggested by Ardex. If you are concerned with warranty policies, please refer to the ARDEX Feather Finish technical data sheet for instructions and warranty information. ARDEX only guarantees recommended and approved applications outlined in the ARDEX Feather Finish technical data sheet. For more information, visit www.ardexamericas.com.

um i think im in love, this table is amazing.

Ahh, thanks Hannah!! We love doing custom stuff for our clients!

one of a kind! your concrete projects are always stellar. i love the gray concrete with the brown wood. great job!

Oh I’m OBSESSED with this!!! Love love love

Thank you friend! You know how much we adore ARDEX and concrete in general! 🙂

Yay Carly! So glad to hear it! That makes me hap, hap, happy! 🙂

Handmade tealight candle holders and decorative tin metal candle holders for sale. Beautiful handmade decoration items for home or office, original artworks and apparel to match your lifestyle. The Minkk Shop set out to bring to you unique quality handicrafts made by talented artisans from all over the world. Check this site: http://www.theminkshop.com/candle-holder.html

This is a fantastic idea!

Freaking AMAZING! 🙂

This is an amazing table! Thank you for the excellent instructions. I want this table, I want to do this treatment. Thank you so much!

Jackie

This comment has been removed by the author.

That is just gorgeous!!

wow!!! so amazing, you two never cease to amaze me with your creativity. seriously, some of the most unique stuff on the internet is on your blog!

I love that machine and table. Very, very, very beautiful, congrats:)

That is awesome! I love the two elements together

Beautiful table what is the size and model of the CNC you used

Beautiful table what size CNC and what model did you use

Just curious how much it would cost to get the engraving done?

I’m curious about the disparity between the two materials shrink / swell rates and if the concrete fills have begun to crack? It appears the depth is around 1/8″ and I would expect that thin of a concrete fill would be prone to cracking / chipping out.

Lovely piece of art

Great & Innovative.

The Art of turning our natural resources into beautiful structures to be enjoyed by many generations to come , is an art form that pulls at the heart-strings of the chosen. One who dabs at the gift is merely depriving themselves and all others who share the love. So wallow in it my fellow comrades. Go with your gut-feeling and don’t be afraid to lead the way.

Is amazing! we are wondering to know how to get your contact or email address..please let us know thanks,,,

Looks nice but how does that thin layer of concrete not crack on a wood surface with expansion contraction?

Love love love the table! What Ardex product did you use???

Would love to see the entire table finished and staged. 🙂

Stunning..so many applications